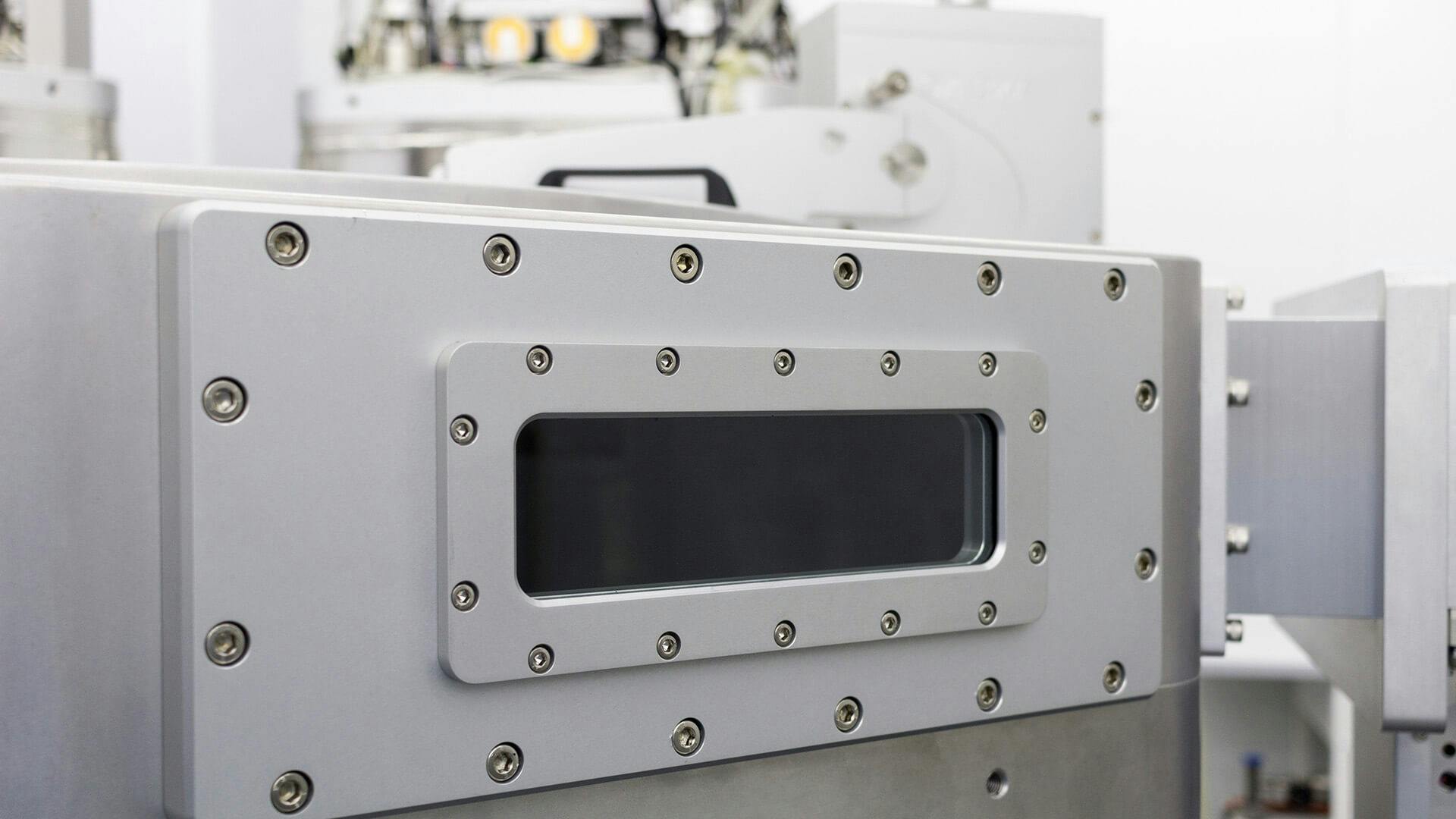

Deposition stages

Read more

Deposition stages have an essential role in advanced coating and thin-film generation systems. This is because they both enhance process efficiency and promote greater substrate coverage as well. Deposition stages are also capable of manipulating substrates in a variety of ways under processing conditions.

If you would like to discuss your project with our engineering team, please contact us.