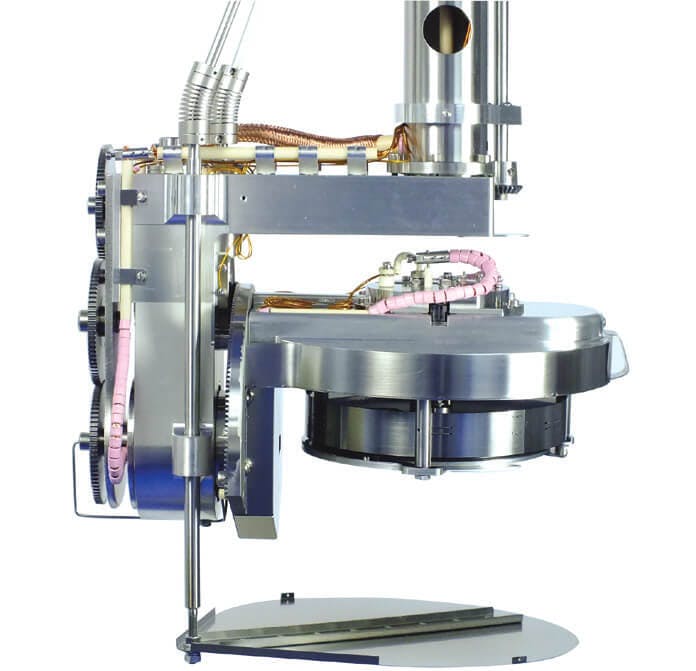

GLAD series

For structured three-dimensional deposition

Glancing Angle Deposition (GLAD) is creating great interest in areas where structured three-dimensional deposition is required. Based on UHV Design's highly successful EpiCentre range, the GLAD stage provides an in-line solution (as with the EC-I Series) but with the addition of substrate tilt. And being an in-line stage, a large range of axial (Z) motion can also be provided.

Key Specifications

- Continuous azimuthal rotation

- Substrate temperature heating to 1200°C

- DC bias ≤ 1 kV for sputter process modification

- RF bias to 100W power for substrate cleaning prior to deposition

- Z-axis travel up to 200mm

- Optional rotation of the entire stage/tilt axis orientation

How it works

By precisely and simultaneously controlling the polar and azimuthal rotations, novel structures can be grown. These have, for example, columnar morphology, nano-helical structures or are structured via anisotropic shadowing. Such materials have applications in many highly topical fields, e.g. photonics, catalysis, bio-compatible materials and fuel cells. As it’s fully UHV compatible, the GLAD stage is suitable for use with all the usual directional deposition sources, e.g. thermal evaporation, physical vapour deposition, pulsed laser deposition and magnetron sputtering.

Additional product detail

- Continuous azimuthal rotation from 0.1 - 20rpm - at any tilt angle from zero to +/- 85 degrees

- Substrate temperature heating to 1200°C, with a solid Silicon Carbide technology option. This provides durability in O2 rich environments

- DC bias ≤ 1 kV for sputter process modification

- RF bias to 100W power for substrate cleaning prior to deposition.

- Ultra-stable plasma during azimuthal rotation

- Z-axis travel up to 200mm to accommodate different source geometries

- Optional rotation of the entire stage/tilt axis orientation to facilitate glancing angle deposition using out-of-plane sources. This requires the use of a differentially pumped rotary feedthrough (optionally fitted)

Series options

Deposition Height Adjustment

The deposition height adjustment option allows the Z position

of the substrate to be adjusted by up to 200mm to optimise the distance from the deposition flux. Other height options available upon request.

DC & RF Bias

Our proprietary substrate biasing technology provides unrivalled flicker-free performance, typically with zero maintenance and long operational life.

Solid Silicon Carbide Heater Element

Solid SiC heaters are manufactured from a conducting solid SiC material in the ß phase and are more robust in all respects. They are durable under mechanical or electrical shocking and when exposed to reactive gases including oxidising atmospheres at high temperature. They are also optimised to give the very best in temperature uniformity. See Figure 1.

Thermocouple Options

Type C and Type K options available with choice of UHV and HV fittings and height adjustment.

Substrate Shutter

Manual or pneumatically actuated substrate shutter to control line-of-sight between substrate and deposition source. See Figure 2.

Homing Sensor

Internal magnetic home switch to align the stage to within 0.1° for automated substrate transfer.

Technical Specification

| STANDARD CONFIGURATION | ||

| Substrate size | 2" (50mm) | 4" (100mm) |

| CF300 / 14" OD system flange | Available | Available |

| CF350 / 16.5" OD system flange | Available | Available |

| Heater element | Silicon Carbide coated graphite (SiCg) as standard (see Options below) | |

| Substrate rotation | Continuous, Stepper motorised, 0.1 - 20 rpm | |

| Substrate tilt | Manual actuation +/- 85o | |

| Insertion length | 240mm flange face to substrate centre | |

| Deposition height adjustment | None (see options below) | |

| Thermocouple | 1 x Type K | |

| Achievable temperature | 1200°C (based on heating a Molybdenum sample) | |

| OPTIONS | ||

| DC & RF bias | DC bias ≤ 1kV, RF ≤ 100W (inc. dark space shielding - must use screened thermocouple options) | |

| Shutter | Manual, pneumatic, steppper motorised | |

| Heater element | Solid Silicon Carbide (sSiC) | |

| Thermocouple options | 1 x (screened) Type K 1 x (screened) Type C | |

| Deposition height adjustment | up to 200mm (other values on request) | |

| Deposition height automation | 24 V DC Motor, stepper motor, Smart Motor, no motor* | |

| (*gearbox only fitted, customer supplies and fits NEMA 23 frame motor) | ||

| Substrate rotation | 24 V DC motor or Smart Motor or no motor* | |

| (*gearbox only fitted, customer supplies and fits NEMA 23 frame motor) | ||

| Substrate tilt automation | Stepper motor, Smart Motor, no motor* | |

| (*gearbox only fitted, customer supplies and fits NEMA 23 frame motor) | ||

| Homing sensor | Internal magnetic switch | |

| Custom insertion length | Available on request | |

| Stage / Tilt axis rotation (via DPRF) | Available on request | |

| Stage / Tilt axis rotation automation | Available on request | |

If you would like to discuss your project with our engineering team, please contact us.