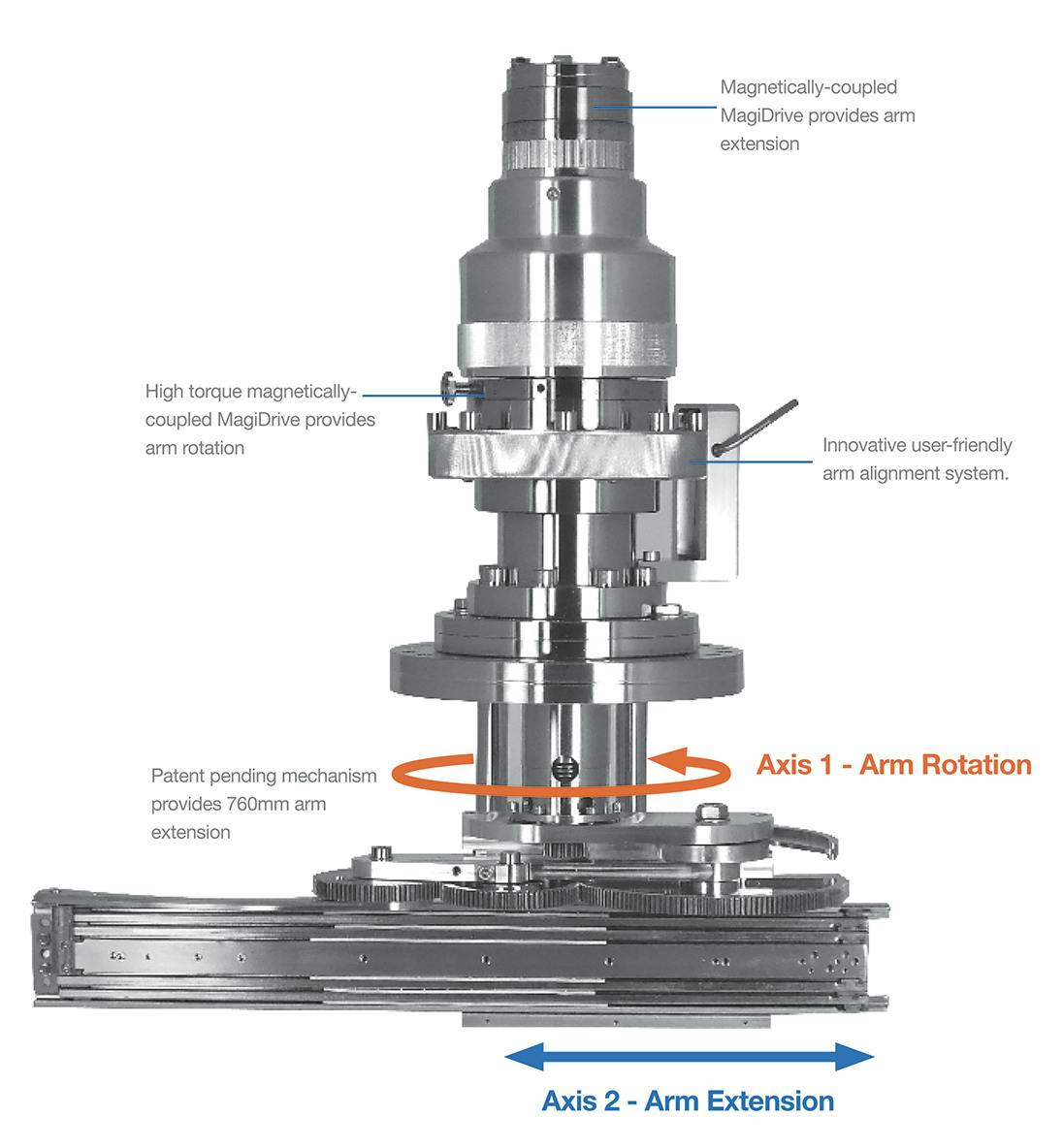

2-axis Rotary Telescopic Transfer Arm

360° rotation and 760mm linear extension

The Radial Telescopic Transfer Arm (RTTA) is engineered for precise sample transfer between multiple chambers in ultra-high vacuum (UHV) systems. Designed to operate from a central radial distribution chamber, the RTTA utilises a high-torque, magnetically-coupled MagiDrive to deliver exceptional performance for radial motion. This innovative system provides superior functionality compared to conventional designs, making it a cost-effective choice for preparation and analysis in demanding vacuum environments.

Key Applications:

How it works:

Versions Available:

User-friendly Manual Arm Alignment

The manual RTTA features an innovative alignment system with adjustable position stops. These stops engage with spring-loaded bearings and can be aligned with port axes to define default angular positions. This design ensures highly reproducible arm positioning.

True UHV Performance

The RTTA operates with the MD64LB and MD40 magnetically-coupled MagiDrive rotary feedthroughs. The MD64LB offers a break-away torque of approximately 40Nm, providing a rigid coupling ideal for arm rotation. The MD40 actuates the telescopic mechanism, ensuring reliable arm extension and retraction.

Motorised 'Talk Free' Concept

UHV Design’s unique mechanical design addresses the issue of arm rotation causing unwanted movement in the extension assembly (axis cross-talk). By linking the rotary motion of the MD64 to the motor mounting of the MD40, this design eliminates the need for complex software adjustments, maintaining accurate sample positioning during rotation.

If you would like to discuss your project with our engineering team, please contact us.