XPP Option

Designed for UHV and XHV applications

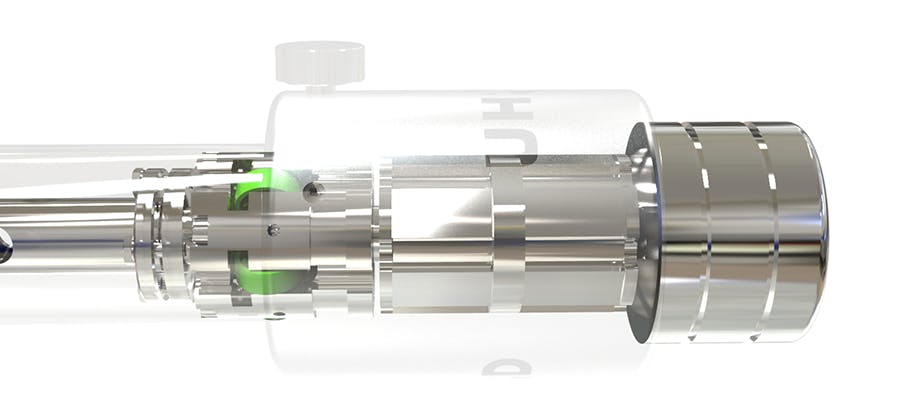

The standard Power Probe range of sample transfer arms provides ultra-reliable, service-free operation in most common sample transfer applications. It follows a robust design philosophy that dictates the use of dry sliding bearings based upon polymers and metal composites - as opposed to rolling element bearings. The trade-off for the unrivalled durability of the PowerProbe design was a pressure burst during actuation. This was caused by the sliding nature of the bearing surfaces.

Key Specifications

- Typically less than one-decade pressure increase during sample transfer

- Rolling all-metal bearings rather than sliding PEEK bearings

- Available in Linear Only, Linear & Rotary, Dual Axes and Elevating Platform variants

Product Downloads

- XLPP technical datasheet (Linear Only)PDF (208kb)

- XPP technical datasheet (Linear & Rotary)PDF (459kb)

- XDAPP technical datasheet (Linear with Inner Rotating Shaft)PDF (426kb)

- XEPP technical datasheet (Elevating)PDF (461kb)

An even more powerful alternative

Although the standard PowerProbe range is recommended for entry lock and UHV applications where small momentary pressure bursts can be tolerated, there is an alternative. For true UHV or even XHV applications, we recommend the XPP option.

Standard Power Probe

Standard PP40 transfer arm uses sliding PEEK bearings as shown in blue. These may result in a two decade pressure increase during sample transfer.

XPower Probe Option

XPP40 uses rolling metal bearings shown in green to minimise pressure rise during sample transfer (typically less than one decade increase)

If you would like to discuss your project with our engineering team, please contact us.